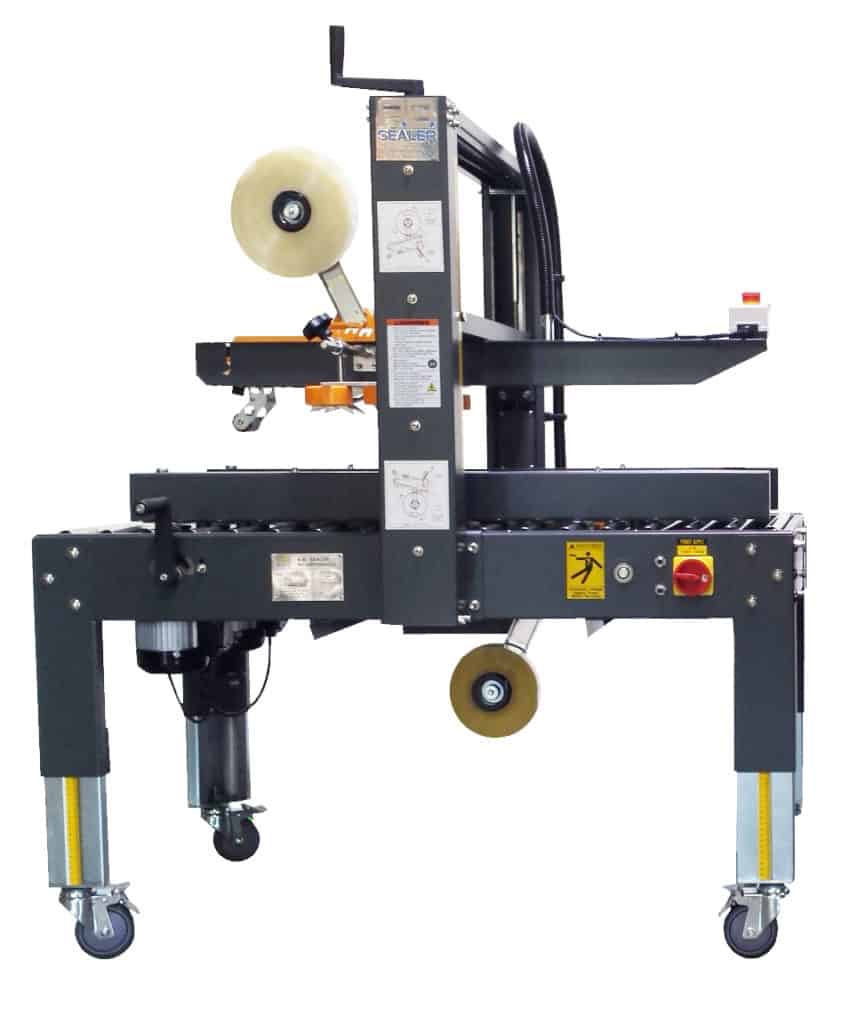

If you move 150 or more cases per day, you will need at least a semiautomatic case sealing machine to help streamline production. Semiautomatic case sealers can be operated with minimal human involvement, allowing you to reduce labor costs and tape cases much faster than any amount of employees taping packages by hand. A semiautomatic taping machine will essentially pay for itself over time by speeding up the packaging and shipping processes and reducing labor costs. However, it is important to understand there are many different types of semiautomatic case sealers. Choosing the right equipment depends on your specific application(s), quantities and case sizes/materials. First Packaging Systems can help you find the right semiautomatic case sealer for your operation.

When you have higher quantities of case sealing needs, an automatic taping machine may be your best option. Automatic case sealers are excellent when you have many same-size cases that need taping. They are also easily adjustable for different materials or case sizes that might be coming through a mass production line. There are machines with both manual and fully automatic size adjustment options available. Automatic taping machines are easy to operate and produce maximum results with minimal labor oversight. Again, not all automatic case sealers are created equal, so it is important to select and configure the best equipment for the job at hand.

Some case sealing applications call for glue rather than tape. This is when a hot-melt glue case sealing machine will give you a significant advantage. This equipment will accurately and consistently apply adhesives. Cases can be sealed automatically with hot-melt glue applied to the top flap with gap-free results. Heavy duty automatic glue machines can be adjusted to accommodate a wide range of case sizes and glue sealing configurations. To find the right automatic glue case sealer for your operation, turn to First Packaging Systems for expert guidance.